Discover Quasar Design Services

Quasar Design Services works with large international manufacturers and product development companies as well as individual inventors and entrepreneurs. Below is a brief overview of our capabilities and services. For more detailed information, please feel free to Contact Us.

Project Management

We handle projects of all sizes and scopes, from single tasks to full-scale design and manufacturing processes. No challenge is too small or too large for our team. We collaborate closely with you to meticulously plan each project, ensuring it is completed on time and within budget to meet your specific requirements.

Product Engineering

Our team can design using virtually any medium, including metal, plastic, stainless steel, and more. Our principal designer holds four U.S. patents, two of which are as a sole inventor. Our projects have ranged from single-medium products to complex projects requiring the integration of multiple materials. Each project is unique, and whether your concept demands high power output, waterproofing, or any other specific requirements, we can handle it.

Ideation

The design process varies in duration and complexity based on the depth and intricacy of your concept. Whether it’s a quick turnaround or requires multiple iterations, our team can produce a range of initial design options, provide constructive feedback on your team's designs, and strategize development throughout the project. No engineering background is needed to bring your ideas to life. We will guide you every step of the way with patience and expertise to meet and exceed all of your design requirements.

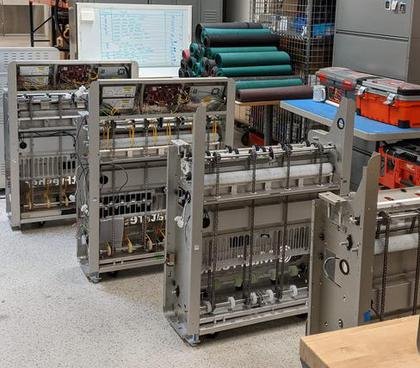

Prototyping & Machining

We understand the importance of selecting the right materials in product production. Our team works with all materials, enabling us to prototype, test, and iterate on designs effectively. With access to a wide range of machines, we can leverage our capabilities to meet various project needs. Throughout the prototyping process, we prioritize design for manufacturability, reliability, and cost-effectiveness, while always keeping our clients’ desires top of mind. We have access to state of the art equipment and the following machining capabilities: 3D Printing, CNC machining, electronics Lab, X-ray machine, laser cutting, UV Printing, wet lab, thermoforming, mold making, and metal casting.

Medical Devices

At Quasar Design, we specialize in creating cutting-edge medical devices that prioritize patient safety and performance. From concept through regulatory approval, our multidisciplinary team combines engineering precision with a deep understanding of healthcare needs to deliver reliable, user-centered solutions. We navigate the complexities of compliance and intellectual property protection to bring innovative devices to market swiftly and securely, transforming clinical challenges into life-saving technologies.

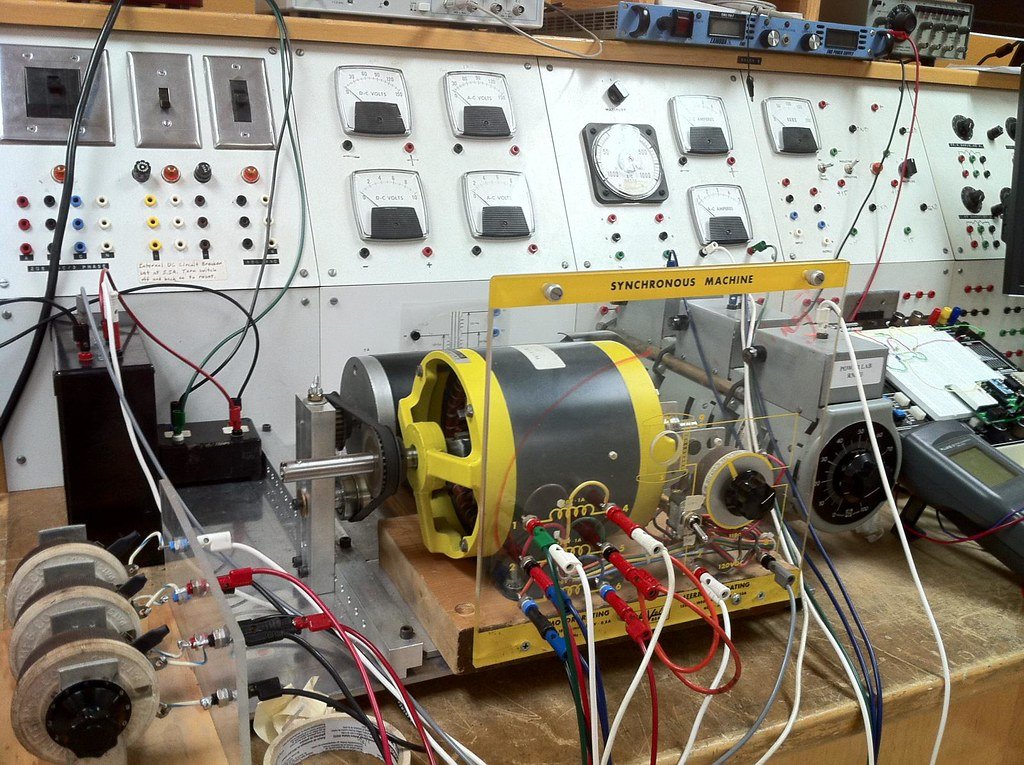

Testing

Lots of products need testing to ensure they are safe for use. Our testing expertise ranges from aging, metrology, sound, force gauge, failure analysis, and more. We can test in-house as well as manage third-party testing for you and your team.

Reverse Engineering

Our engineers possess the expertise to analyze any product and determine what materials it is made of and how it is made. This capability is invaluable for inventors, manufacturers, and large organizations aiming to develop or enhance existing products.

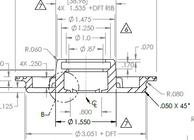

SolidWorks and Fusion 360 3D Modeling

We utilize top-of-the-line digital 3D modeling software, including SolidWorks and Fusion 360. If you have designs in AutoCAD, LightWave, VisualMill, Rhinoceros, 3D Studio Max, or other softwares, we’re happy to work with those as well.

Design Drawings

Thoroughly communicating your inventions through formal design drawings is crucial for accurate manufacturing and securing intellectual property rights. Our team excels at producing these detailed drawings with the utmost precision, while always keeping your goals in mind.

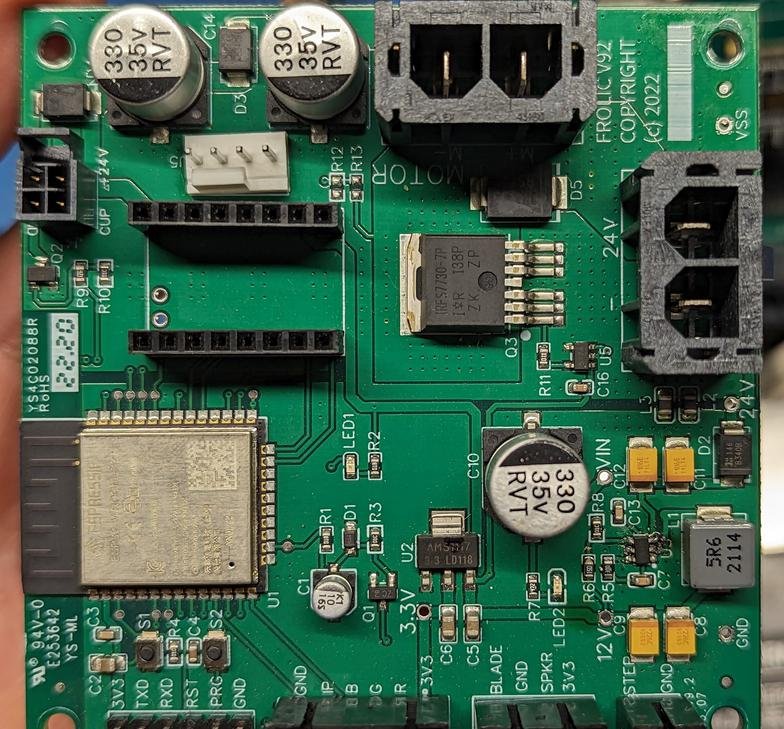

Electronic Design

Our engineers possess extensive expertise in electronics and electrical circuits. We can assist you in designing any device, instrument, or circuit and produce prototypes for testing. More specifically, we design IOT devices, motor controllers, automation and robotics. For examples of our electronic designs, see Our Work.

Firmware

Our team specializes in designing firmware for IoT devices and various other applications, ensuring that your products perform flawlessly. Each firmware solution undergoes a rigorous qualification process to guarantee proper functionality and reliability. We ensure seamless integration of firmware with all your electronic and mechanical devices, creating a cohesive and efficient system that enhances your product's performance.

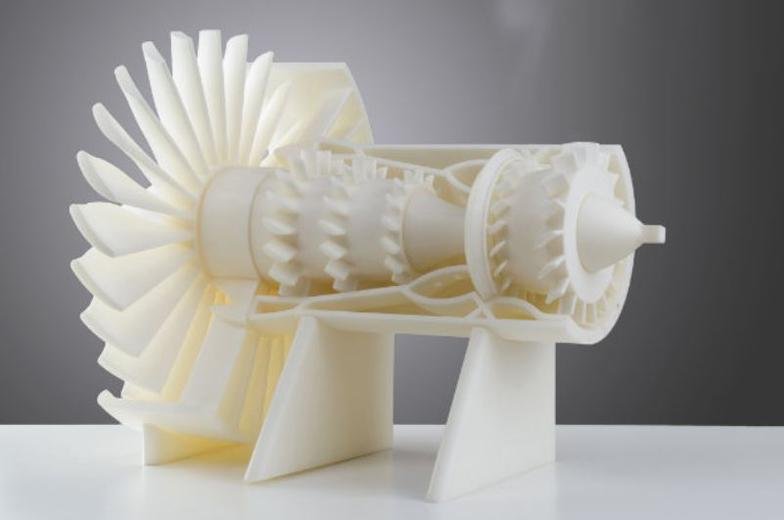

3D Printing

Our 3D printers produce prototypes in ABS, PLA PETG, TPU, Carbon Fiber, and Nylon. They create objects with a build volume of 14” x 14” x 10”. We accept solid models in STL and STEP file formats as input, as well as open source files. We can print items with a detailed resolution around 250 microns.

Thermal Engineering

Our thermal engineering capabilities focus on optimizing thermal performance and efficiency in your products. We conduct comprehensive analyses to assess heat transfer, thermal management, and temperature distribution, ensuring that your designs meet the required performance standards. By leveraging advanced simulation tools and techniques, we can identify potential thermal issues early in the design process and recommend effective solutions, helping you achieve reliability and longevity in your products.

FEA Analysis

When engineering products, a formal analysis of structural integrity, heat transfer, fluid flow, mass transport, or electromagnetic potential is often required. Our team can conduct these analyses and provide your team with a comprehensive assessment, along with recommendations for any necessary adjustments.

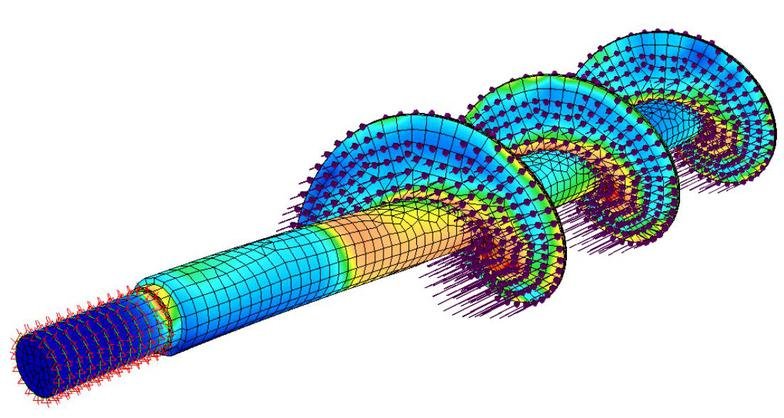

CFD Simulation

Many product solutions require technical simulations to analyze fluid dynamics and movement. Whether it’s assessing how the product interacts with its environment or evaluating its performance, computational fluid dynamics (CFD) simulations may be essential for your project's success.

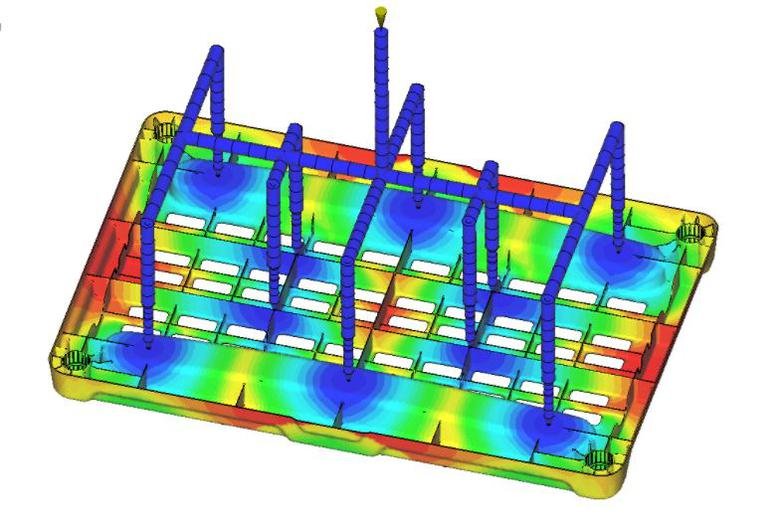

Moldflow Analysis

If your product will be constructed using a plastic mold, it’s essential to analyze how that mold will support your design. Our team offers moldflow analysis to evaluate and make any necessary adjustments, ensuring optimal performance and quality for your mold.

IOT Consulting

As products and people become increasingly interconnected, the Internet of Things (IoT) is transforming our way of life. Quasar Design can assist your team in planning and engineering your products to seamlessly integrate both hardware and software solutions.

Sourcing Nationally and Internationally

Trying to find a manufacturing partner? We have an extensive network of trustworthy manufacturers both in the U.S. and around the globe. We’re dedicated to helping you find the perfect manufacturing partner for your product.

Small Batch Manufacturing

When you’re ready to take the next step, we can help you transition from your minimum viable product (MVP) to beta testing through our small-scale manufacturing capabilities. This process allows you to refine your product and gather valuable feedback before full-scale production, ensuring optimal performance and market readiness.